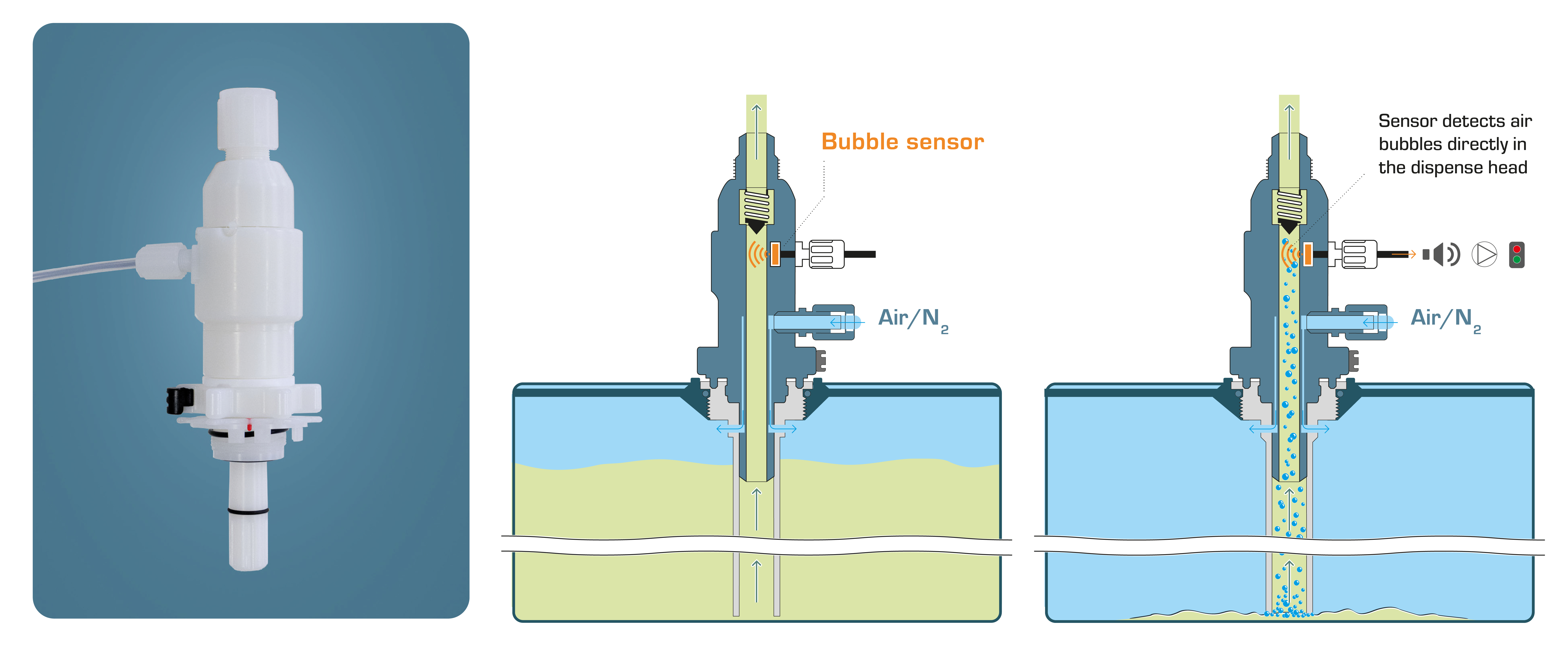

Report empty status easily and fully automatically. Dispense heads with integrated bubble sensor enable automatic operation.

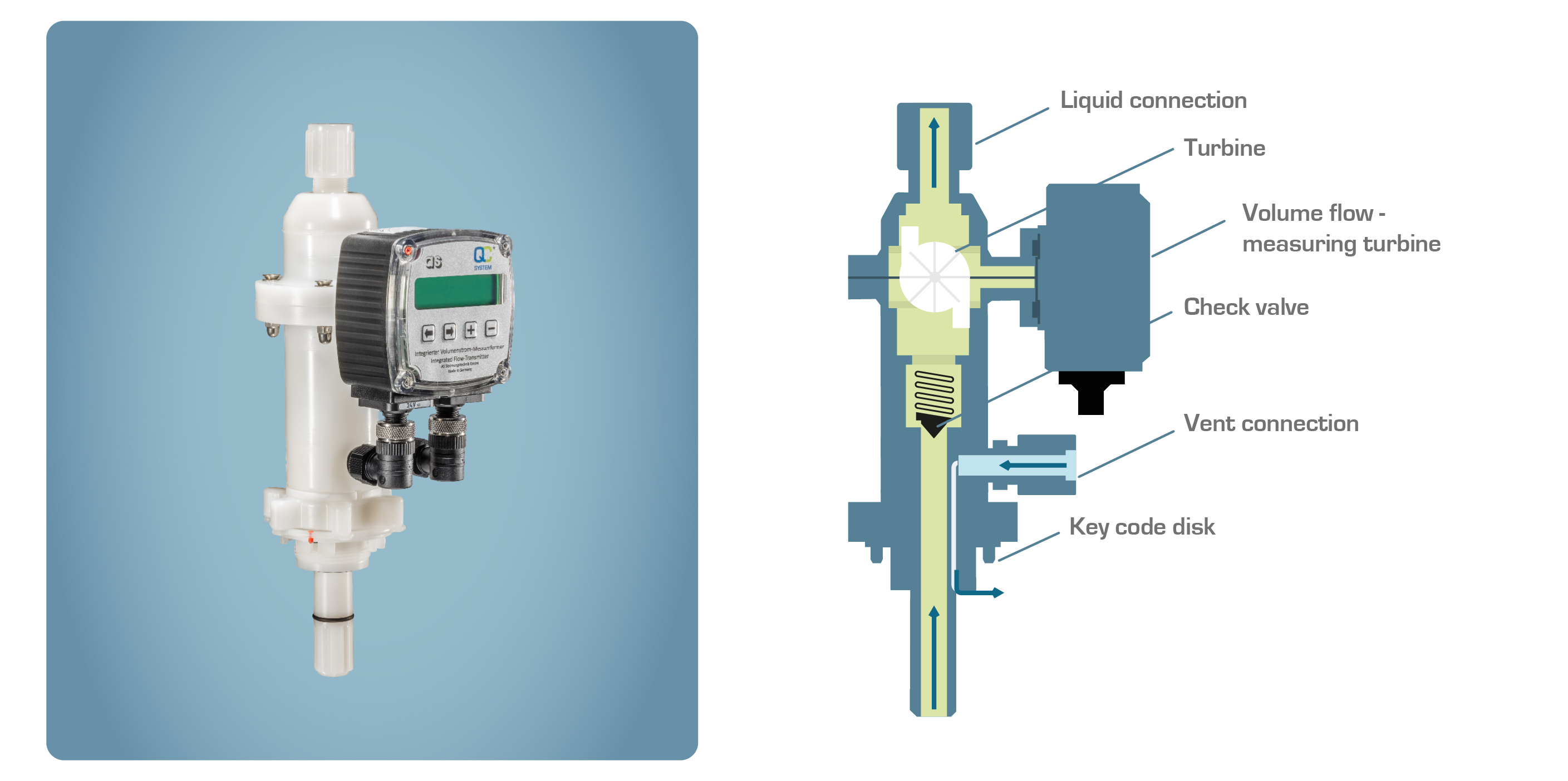

QC2 dispense head with integrated volumetric flow-measuring turbine that displays the flow rate in real time for precise dosing from the container.

Two Main Options:

- Totalizer-allows verification of flow during dispensing process

- Ensures Flow Rate

- Verifies volume transferred

- Batch control - easy integration for small transfer volumes. Ability to transfer only specified amounts.

- Dosing and Mixing without the need of expensive metering pumps

- Can be easily be programmed to send signals to process controls

Technical Data:

| QC2-Series max flow rate: |

|

Materials of construction for body: |

|

| Other wetted parts: |

|

| Key Code: |

|

| Flow Transducer: |

|

| Measurement Data: |

|

| Operating Temperature: |

|

Pressure Loss: |

|

| Electrical Connections: |

|

| Item Numbers: | Batch Controller DH-DCF-PE-XXX-F1/2″-F3/8″ (with FKM seals) DH-DCE-PE-XXX-F1/2″-F3/8″ (with EPDM seals) Totalizer DH-DTF-PE-XXX-F1/2″-F3/8″ (with FKM seals) DH-DTE-PE-XXX-F1/2″-F3/8″ (with EPDM seals) |

- Measuring certificate with calibration data included. Calibration with water temperature of 20 degrees Celsius.

- Particles contained in the medium that are greater than 100 µm may cause blockage.